Handling and separating stacked metal sheets is an everyday challenge for shops and fabricators. Prying thin metal sheets apart by hand is inefficient and dangerous. However, magnetic sheet fanners provide a clever solution for quickly and safely separating stuck sheets. These specialized tools utilize powerful magnetic fields to fan and repel metal sheets from each other. This article examines a magnetic sheet fanner, explaining what it is and how it works.

What is a Magnetic Sheet Fanner?

Magnetic sheet fanners are a very helpful tool to separate metal sheets stacked together quickly. They use strong magnets to lift and fan out the sheets so you can pick one off the top of the stack. This makes handling and sorting metal sheets much simpler and faster.

Magnetic sheet fanners come in different sizes and strengths. But they all do that same primary job of using magnetic force to repel metal sheets away from each other. This allows individual sheets to be removed without prying them apart by hand.

Sheet metal workers, machinists, welders, and other metal fabrication professionals rely on magnetic sheet fanners daily. They have become indispensable for efficiently handling stacked sheets of steel, stainless steel, galvanized steel, and other magnetic metals.

How Magnetic Sheet Fanners Work?

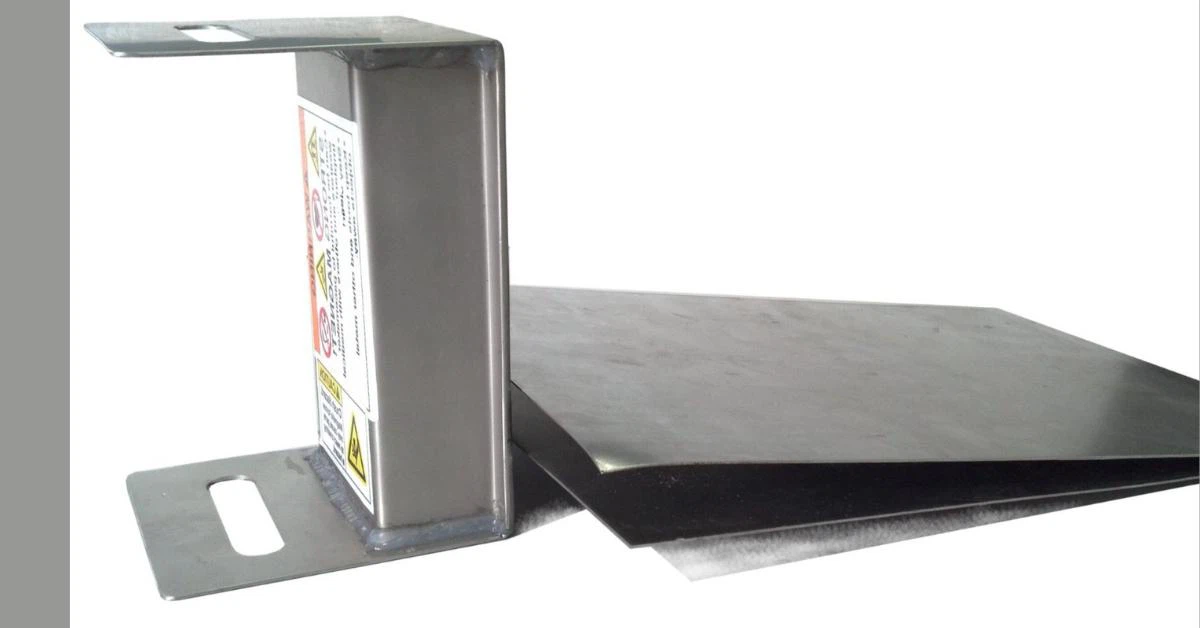

A magnetic sheet fanner is a handle attached to a long magnetic bar or plate. The magnetic bar is kept inside a stainless steel or aluminum covering that does not stick to magnets. Very strong rare earth magnets make a powerful magnetic field throughout the bar's length. When the bar comes close to a pile of thin metal sheets, the magnetic field goes through the top sheets and makes them stick to the bar like a magnet.

When the magnetic bar is brought near a stack of thin metal sheets, the magnetic field penetrates the top few sheets and causes them to attach to the bar magnetically.

As the bar is moved across the sheets, the attached sheets bend and fan out from the stack. This fanning action separates the top sheet from the others below it. When the magnet spreads out one part of the sheet, the sheet can be picked up quickly.

The important thing is that the magnet's pull is powerful enough to lift and curve the sheets but not so powerful that the sheets stay stuck to each other. So, a properly calibrated magnetic field allows temporary magnetizing and fanning out just the top few sheets.

The thicker the sheets, the stronger the magnets must penetrate deep enough into the stack. So, magnetic sheet fanners come in various magnetic field strengths suitable for different gauge metal sheets.

Types of Magnetic Sheet Fanners

There are several main types of magnetic sheet fanners to suit different operation needs and workflow setups.

Permanent magnetic fanners

Permanent magnetic fanners utilize fixed permanent magnets to generate the fanning field. They provide consistent, reliable performance and are cost-effective for low to medium-volume sheet handling.

Switchable magnetic fanners

Switchable magnetic fanners allow the magnetism to be turned on and off via a power switch or electronic control. This adds versatility for tasks where sheets need to be manually loaded/unloaded within the magnetic field. Switchable fanners are more heavy-duty for frequent high-volume fanning.

Machine Mount magnetic fanners

For automated high-speed production, machine-mount permanent magnetic fanners are designed to attach to equipment like stamping presses and slitting lines. They quickly fan sheets at the point of output from the machines.

Pivoting permanent magnetic fanners

Pivoting Permanent Magnetic Sheet Fanners pivot on bearings to fan irregularly shaped parts. The pivot design allows contact with irregular sheets. Two magnetic options are available - permanent ceramic magnets or stronger Neo Rare Earth magnets. It is ideal for effectively fanning irregularly shaped metal sheets.

Whether basic or heavy-duty, permanent or adjustable, a magnetic sheet fanner variety is suitable for any operation's needs and budget.

Benefits of Using Magnetic Sheet Fanners

Magnetic sheet fanners have many advantages compared to moving metal sheets by hand. They save a lot of time and work. Jobs with sheet metal can go much faster. Fanners also make the work safer.

Workers don't need to force tools dangerously between tight stacks of sheets. This prevents many hand injuries from the sharp metal edges. The fanned-out sheets are neatly arranged and ready for the next step. This makes the workflow smooth and orderly.

One person can use a handheld or overhead fanner safely by themselves. Two people don't need to tug at stuck sheets. The fanners are gentle on machinery, too. They handle the sheets precisely with less wear on rollers and parts.

Fanners work on all types of metal sheets - cold rolled, hot rolled, galvanized, stainless, and aluminum coated. They last a long time with little maintenance since there are few moving parts to break. Mostly just keeping the fanner clean. Magnetic sheet fanners have many benefits and save time and effort in any sheet metal fabrication shop.

Creative and Unusual Uses for Magnetic Sheet Fanners

While designed for the metal fabrication industry, magnetic sheet fanners have creative and unexpected uses. Fanning thick books - The magnetic fields penetrate deeply enough to fan out pages of thick books for scanning or copying without damaging the spine by overly bending.

Holding tools on vertical surfaces - The magnetic bar can temporarily hold steel tools, nails, drill bits, etc., conveniently on a steel work table, machine housing, fridge, etc. Retrieving metal objects - Retrieve dropped nuts, bolts, parts, etc., from tight spaces like machinery, drains, and cracks simply by passing the fanner nearby to attract them.

Magnetic stirrer - Transform the fanner into a magnetic stirrer for chemistry experiments by laying it flat and moving it in liquids. Spin steel fleas for navigation studies, too. Automotive dent puller - Attach a handheld fanner to sheet metal dented car body panels; the strong magnetism helps pop small dents out.

How To Choose a Magnetic Sheet Fanner

The key aspects to evaluate when choosing the optimal magnetic sheet fanner include:

Sheet Thickness: The maximum sheet thickness the fanner can properly fan out sets the gauge rating. Standard fans handle 25-28 gauge. Heavy-duty models lift up to 1/4" thick sheets.

Sheet Width: The overall fanning bar length should match the sheet width being handled. Too short won't fully fan sheets. Too long leaves gaps.

Sheet Material: Know the material to ensure the magnets attract them properly. Standard fans only lift steel containing iron. Special titanium fans are needed for stainless steel or aluminum sheets.

Operation Type: Assess if a handheld, overhead, or conveyor belt style fanner fits best with your workflow and facility layout.

Magnet Type: Permanent magnet fanners are simple and reliable. Electro-permanent powered magnets provide variable strength control and energy savings.

Single/Dual: Single bar length up to 5 feet works well for most purposes. Dual shorter bar fanners are better suited for wide sheet handling above 5 feet.

Handling Volume: Estimate your daily/weekly sheet fanning needs to determine the required fanning speed and duty cycle. High volume needs demand heavy-duty, continuous-use fanners.

Mounting: Most overhead and conveyor fanners include mounting hardware to install above-sheet stacks and machinery easily. Handheld units just need a storage hook.

With these criteria in mind, you can select the ideal magnetic sheet fanner with the right features for your specific metal fabrication needs and budget. Investing in a quality magnetic fanner will provide many years of smooth, reliable sheet handling.

Proper Use and Care of Magnetic Sheet Fanners

Using magnetic sheet fanners properly keeps them working well for a long time. First, always wear heavy gloves and eye protection for safety. Turn on the magnets before touching the sheets to avoid catching fingers. Move the magnet bar across the whole length of the sheets to spread them apart evenly.

Lift the fanned sheets straight without dragging to prevent scratches. Only fan the top few sheets needed, not the whole stack, which wastes time. Don't let the fanner touch the sheets directly; this weakens the magnets.

Demagnetize tools sometimes so they fully recharge. Wipe off any grime, metal bits, oil, etc. that build up on the magnet housing. Avoid banging or dropping fanners, which can crack magnets or damage inside parts. Check handles, mounts, and cords are fully secured with no looseness.

Don't exceed the rated sheet thickness to prevent overload damage. Hang handheld units vertically and cover conveyor/overhead fanners when not in use. Following the maintenance instructions will keep your magnetic fanner working properly for many years. Proper use and care improve safety and productivity.

Conclusion

Magnetic sheet fanners safely and efficiently separate metal sheets using powerful magnetic fields to temporarily lift and spread out the top sheets for easy removal. Fanners come in handheld bars overhead mounts and are pivoted to integrate into any metal fabrication workflow, avoiding hand injuries and increasing speed. Considerations for selecting the ideal fanner include magnet strength, bar length, and duty cycle. Proper use and care optimize performance.

Advancements lead to stronger, more versatile designs, but any quality magnetic fanner improves sheet handling. Essential shop tools that quickly pay for themselves in time and labor savings.