Are you curious about the machines that keep our food safe and free from contamination? Look no further than food processing magnets! These powerful devices use the principles of magnetism to remove unwanted metal particles from food products, ensuring that your food is of the highest quality and safety standards. The magnetic separator principle is simple yet effective, using a strong magnetic field to attract and hold ferrous or magnetic particles as they pass through the separator. There are different types of machines available, including plate magnets, magnetic grids, and pulleys, tailored to specific production processes.

For the food industry, magnetic metal separators are specifically designed to remove metal particles from food products. This technology is widely used in various applications, from processing raw materials to meat, dairy, and snack foods. While there are challenges to using magnetic separation technology, such as product flow and maintenance, the benefits are numerous. Using these machines can lead to improved product quality, increased production efficiency, cost savings, and regulatory compliance. So next time you enjoy a delicious snack or meal, remember the crucial role that food processing magnets play in keeping your food safe and free from contamination.

What are Food Processing Magnets?

Food processing magnets, also known as magnetic separators, are machines that use the principles of magnetism to remove unwanted metal particles from food products. These machines typically consist of a magnetic metal separator, which attracts and removes metallic contaminants from the product stream.

Magnetic Separator Working Principle

Have you ever wondered how those tiny metal particles get removed from your food products? It's all thanks to the remarkable technology of magnetic separators!

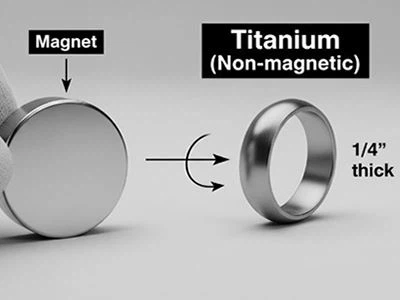

At the core of a magnetic separator is a powerful magnetic field that attracts and holds onto ferrous or magnetic particles, while non-magnetic particles pass through unaffected. This process ensures that only safe and high-quality food products make it to your table.

The strength of the magnetic field used depends on the size and type of metal particles being removed. It can range from a few hundred Gauss to several thousand Gauss, depending on the specific requirements of the production process. This strength is measured in units called Gauss or Tesla, depending on the type of magnet used. Higher magnetic field strength is required for larger metal particles, while smaller particles can be removed with lower field strength.

The magnetic field is generated by either a permanent magnet or an electromagnet. Permanent magnets use naturally magnetized materials to create a constant magnetic field, while electromagnets use an electric current to generate a magnetic field that can be adjusted as needed. It's incredible to think that such a straightforward process can have such a significant impact on the safety and quality of our food products. With the help of magnetic separation technology, we can ensure that our food is free from harmful metal particles and ready to be enjoyed by everyone.

Magnetic Separator Machine

When it comes to removing unwanted metal particles from food products, there are a variety of magnetic separator machines available to choose from. These machines range from simple plate magnets to more complex options, all designed to meet the specific requirements of the production process.

Let's take a closer look at some of the most common types of magnetic separators used in the food processing industry:

1. Magnets for plates: These uncomplicated magnetic separators are made up of a plate magnet set on a chute or conveyor. Any ferrous or magnetic particles are drawn to and held by the plate magnet when the product stream passes over it.

2. Grate Magnets: Similar to plate magnets, grate magnets consist of a series of magnetic tubes or bars arranged in a grid pattern. The product stream flows through the grid, and any ferrous or magnetic particles are attracted to the tubes or bars, ensuring they don't contaminate the food products.

3. Magnetic Pulleys: These magnetic separators consist of a belt conveyor with a magnetic pulley at the end. As the product stream passes over the magnetic pulley, any ferrous or magnetic particles are attracted and held by the magnet.

4. Drum Magnets: These magnetic separators consist of a rotating drum with a magnet inside. The product stream is fed into the drum, and any ferrous or magnetic particles are attracted to the magnet and held on the drum's surface.

Choosing the right type of magnetic separator depends on several factors, including the size and volume of the product stream, as well as the specific needs of the production process. No matter which type of magnetic separator you choose, the result is the same: high-quality, safe food products that consumers can trust.

Magnetic Metal Separator

By using the strength of magnets to pull dangerous metals out of the materials being processed, magnetic separation works. This procedure is essential in sectors like food, dairy, grain and milling, chemical, plastics, oil, textile, recycling, powder and bulk, mining, and nonwovens where product purity and safety are of the utmost importance. You can avoid potential legal disputes, negative publicity, product recalls, and—most importantly—severe customer injury by making an investment in magnetic separation solutions like those we provide at our magnetic separator manufacturing company.

For various industries, including the mining, cement, and food sectors, we provide a wide range of solutions, such as lifters, metal detectors, and magnetic separators. Our tramp oil removal systems and permanent magnetic separators also aid in preventing damage to processing equipment, ensuring the effective and profitable operation of your company. You can be sure that your products and equipment will be secure, pure, and free of dangerous materials thanks to our knowledge in magnetic separation and our dedication to providing high-quality solutions.

Let's take a closer look at some of the most popular magnetic separators:

● Drawer Magnets: Ideal for easy-flowing, dry materials in industries such as Recycling, Food, Powder and Bulk, and Plastics, these magnets remove fine tramp metal contaminants and come in multiple construction grades with stainless steel housings.

● Drum Magnets: Great for high-volume applications and continuous removal of ferrous contaminants, Drum Magnets are used in industries such as Plastics, Recycling, Grain and Milling, Powder and Bulk, Aggregate, Mining, and Minerals.

● Plate Magnets: These magnets are perfect for handling more abrasive products and can easily be installed in chutes or above/below conveyor drive pulleys. They are often used in the Plastics, Recycling, Food, Grain, and Milling, and Powder and Bulk industries.

● In-Line Magnets: Equipped with rare earth magnets, In-Line Magnets are designed for unobstructed product flow and are typically used in the Plastics, Recycling, Food, Grain, and Milling, and Powder and Bulk industries.

● Magnetic Liquid Traps: Used in the Food, Grain, and Milling, and Powder and Bulk industries, these magnets remove ferrous tramp metals from liquid processing and conveying lines and can handle acidic food products.

● Hump Magnets: Perfect for high-volume product flow, Hump Magnets increase protection against entrapped ferrous materials while preventing build-up and bridging in industries such as Food, Grain and Milling, Powder and Bulk, and Non-Woven.

● Grate Magnets: Installed in hoppers, pits, chutes, housings, and bins, Grate Magnets are used in industries such as Plastics, Food, Grain and Milling, and Powder and Bulk to remove tramp metals from larger flowing materials.

● Wedge Magnets: These magnets are installed in narrow, vertical, or steeply inclined chutes in gravity flow applications and protect equipment from damage caused by tramp metals. Wedge Magnets are commonly used in the Grain and Milling industry to process particulate or semi-solid materials.

Industrial Magnetic Separation

In order to assure the safety and quality of food products, industrial magnetic separation is a crucial component of the food processing sector. Unwanted metal particles are removed from food products using magnetic separators, lowering the possibility of contamination and product recalls. What specific uses for magnetic separation technology exist in the food sector, though? Let's look at this:

1. Processing of Raw Materials: During harvest or transportation, metal pieces can contaminate raw commodities including grains, nuts, and seeds. Before further processing, these metal fragments are removed using magnetic separators to guarantee the end product's quality and safety.

2. Processing of Meat Products: Metal shards can easily get into meat products during the preparation of meat. A few products that can benefit from the use of magnetic separators to eliminate unwelcome metal particles include ground beef, sausage, and chicken nuggets.

3. Processing of Dairy Products: Dairy goods including milk, cheese, and yogurt can also include metal flakes. In order to guarantee that the finished product is safe for ingestion, magnetic separators are essential for removing these pollutants.

4. Processed Snack Foods: Popular foods like popcorn, pretzels, and potato chips are processed snacks that may contain metal shards. These pollutants are eliminated using magnetic separators, allowing consumers to enjoy their preferred snacks worry-free.

As you can see, there are a wide range of uses for magnetic separation technology in the food processing sector. Magnetic separators are crucial pieces of equipment that serve to assure the safety and quality of our food products, from the processing of raw materials to the creation of snack foods.

Benefits of Magnetic Separation in Food Processing:

The use of magnetic separation technology by manufacturers to enhance product quality, expedite production, reduce costs, and adhere to regulatory standards is transforming the food processing sector. Let's examine the advantages of utilizing this technology in more detail:

Improved Product Quality: The capacity of magnetic separators to remove metal bits from food products is one of their most important advantages. These pieces can be found in a number of places, such as machinery and processing equipment, and they can seriously endanger the health of consumers. Magnetic separators enhance product quality and lower the possibility of contamination by eliminating these fragments, guaranteeing that the food is safe for eating.

Efficiency Gained: Magnetic separators are highly effective in removing metal shards from food goods. This implies that the manufacturing procedure can be shortened, saving money and resources while still producing food. This not only enables businesses to produce more but also guarantees that goods are produced fast and effectively.

Cost Savings: Over time, magnetic separators can help food processing businesses cut costs. Companies can prevent the costs of product recalls, lost income, and reputational harm by lowering the likelihood of product recalls and increasing production efficiency. Utilizing magnetic separators can also assist businesses in lessening the wear and tear on processing equipment, extending the life of the machinery and lowering maintenance expenses.

Compliance with Regulations: In the food processing sector, regulatory compliance is crucial. Regulation non-compliance may result in penalties, product recalls, and even legal action. Companies can make sure that they are in compliance with legal regulations like the FSMA in the US by employing magnetic separators. Magnetic separators are a vital tool for businesses wishing to adhere to standards and guarantee the safety of their products because they are a tested method for removing metal fragments from food products.

Challenges of Magnetic Separation in Food Processing:

The food processing business has been transformed by magnetic separation technology, but it is not without difficulties. Here are some of the major issues and possible solutions in more detail:

● Product Flow: Ensuring a steady product flow when employing magnetic separators is one of the key challenges. The separator's performance may be jeopardized if the flow is erratic or unequal. This may result in an insufficient separation of metal particles and potential product contamination. It is crucial to design the production line to provide a constant and consistent product flow to solve this difficulty.

● Maintenance: To ensure optimal operation, magnetic separators need routine maintenance much like any other piece of machinery. To do this, magnets and other components must be cleaned and changed as necessary. Equipment breakdown and increased downtime are potential consequences of neglecting maintenance. Establishing a regular maintenance schedule and carrying out routine inspections to find any potential problems are crucial steps in preventing these problems.

● Product Sensitivity: During the separation process, several food goods, such as powders and chocolate, may be harmed because of their sensitivity to magnetic fields. The texture, flavor, and general quality of the product may alter as a result. The right kind of magnetic separator must be chosen, and it must be made sure that the magnetic field intensity is appropriate for the particular product being processed to reduce the danger of product damage.

The food processing industry can continue to enjoy the many advantages of magnetic separation technology, including enhanced product quality, increased production efficiency, cost savings, and regulatory compliance, by identifying these difficulties and putting plans into place to address them.

Conclusion

Magnetic separation technology has revolutionized the food processing industry by enabling safe and high-quality food products to be produced. The remarkable technology at the core of magnetic separators uses a powerful magnetic field that attracts and holds onto ferrous or magnetic particles, while non-magnetic particles pass through unaffected. The strength of the magnetic field used depends on the size and type of metal particles being removed, and there are a variety of magnetic separator machines available to choose from, depending on the specific needs of the production process. Magnetic metal separators have also been designed to remove metal particles from food products, and there are various types of metal detectors available for this purpose. Magnetic separation technology has numerous benefits, including improved product quality, increased production efficiency, and reduced risk of contamination.