When machining and manufacturing, securing the workpieces properly during various operations is very important. These are the tools that cannot be dispensed with for this purpose. They make it possible to fix ferromagnetic materials in place as a reliable and effective clamping method.

Therefore, what are the working principles of magnetic chucks? This question is answered here by looking at their types, advantages, applications, factors to consider when using them, and maintenance and safety.

What Is Magnetic Chuck?

A magnetic chuck is a device used in machining and manufacturing processes, such as milling, grinding, and turning, to hold ferrous workpieces in place during these operations.

The chuck functions on the principle of magnetism, pulling the workpiece, thus ensuring stability and accuracy while machining it. Because their strengths are different everywhere, a dependent selection of permanent magnetic or electromagnet chucks is available.

How Does A Magnetic Chuck Work?

A magnetic chuck is a device that uses magnetism to hold down ferrous metal workpieces when machined. Here's how it works:

Magnetic Field Generation: The attraction generated by permanent magnets or electromagnets arranged in a predetermined configuration on the magnetic chuck. Permanent magnetic chucks have unchanging polarity, while electromagnetic ones use wire coils through which electric current flows to create a magnetic field.

Attraction of Ferrous Material: From the field, induction results from its polarity when a ferrous workpiece is placed atop the surface of the magnetic chuck. Opposite poles attract each other, creating a holding force that fastens the workpiece tightly onto it.

Stand Precision: During machining operations, the piece remains still without any visible movement or noise because of firm gripping by the magnetic chuck. This promotes accuracy, hence producing fine finished products of high quality.

Adjustability (for Electromagnetic Chucks): Electromagnetic chucks allow for adjustment. Depending on the requirement of the machining process, varying electric current supplied to the wires controls the strength of magnetism and the holding force that it exerts. This allows for versatility in holding various sizes and shapes of workpieces.

Release Mechanism: After machining, the magnetic chuck can be deactivated to release the workpiece. For electromagnetic chucks, this involves turning off the electrical current to the coils, while for permanent magnetic chucks, the magnetic field naturally dissipates.

Types of Magnetic Chucks

Magnetic chucks are classified according to their magnet properties.

Permanent Magnetic Chucks

A permanent magnetic chuck comprises permanent and fixed poles that draw the workpiece continuously. These include magnets with opposite poles slapped on a top plate encased in a unit.

They operate without electricity so that they can be easily operated and maintained. Though they are simple and long-lasting, they may need more intensity of holding force for heavy-weight materials.

Electromagnetic Chucks

The magnets don't function in electromagnetic chucks unless an electric current flows through them. This type of chuck can be switched off, releasing a part quickly and easily once turned off; a workpiece cannot be released if there is still an electrical flow.

Direct current passes through the coil, magnetizing the inner core and forming a magnetic field in these chucks. Unlike permanent magnetic chucks, they develop greater adhesion power and can safely hold irregularly shaped products.

Electro-Permanent Magnetic Chucks

Electro-permanent magnetic chucks are a combination of electromagnetic and permanent types. They require an electric shock to lock and unlock the workpiece. They hold the workpiece firmly even when there is a power cut, thus preventing accidental release.

Each magnet in an electro-permanent chuck is surrounded by an electrical coil, allowing for quick changeover in polarity. The coils also control the magnetic pull exerted by the chuck during machining operations, making it versatile and stable.

Advantages of Using Magnetic Chucks

Magnetic chucks have many benefits that make them useful for various applications in machining and manufacturing processes.

Secure Holding: This implies that magnetic chucks provide a firm grip on the workpiece to ensure it remains fixed properly during machining operations, increasing accuracy and precision.

Versatility: By securely holding down any workpiece with or without flat surface areas, large or small sizes, magnetic chucks are very flexible for machining setups.

Reduced Setup Time: Magnetic chucks reduce the time required to prepare a machine setup compared to traditional clamping systems. They do not require bulky clamps or fixtures and, thus, can be used to position workpieces on their surface rapidly. This leads to improved performance and increased productivity during machining operations.

Accessibility: Magnetic chucks provide unimpeded accessibility to the whole workpiece surface, allowing multiple-sided machining without repositioning. The machining process is improved by reducing the complexity of setups and, therefore, saves time and energy.

Improved Surface Finish: Magnetic chucks help minimize vibrations and movements when machining by holding the workpiece firmly. Consequently, this gives a smoother surface finish on the machined part, which means fewer additional finishing processes are needed, leading to better product quality.

Cost-Effectiveness: Apart from its operational advantages, there is also cost-effectiveness attached to using magnetic chucks for work holding. These types have a long life span and need less maintenance, thus becoming more economical than other workholding methods.

Safety: Besides ensuring no displacement or movement of a part under processing that could lead to accidents in production environments, they offer rigid security against mishaps generated by any slight dislodgement of any workpiece during machining operations. Additionally, they eliminate the need for manual clamping, reducing the risk of operator injury.

Applications Of Magnetic Chuck

Due to their flexibility and efficiency in work holding, magnetic chucks are used across various industries. This is where they find the most extensive use.

Metal Cutting Processing: Magnetic chucks are widely employed in metal cutting processes such as turning, milling, grinding, planing, and drilling, among others. They can be used for general machine tool applications and machining center applications without any changes required to the original design of the machine tools.

Quick Mold Change: This name is critical in quick mold change measures, particularly in injection molding machines and ceramic dry presses. It does not require a lot of alteration as only one control is needed by it to keep track of time refreshing the molds at high speed; this is possible because of injection molding machines that have electro-permanent magnetic chucks, which become profitable with more significant profit margins and thus most users prefer them over other types.

Magnetic Lifting: Magnetic chucks are used in lifting/handling operations, primarily on individual steel plates related to industries such as automotive axles, car chassis, or container shipbuilding. For example, steel plates handled using an electro-permanent magnetic lifting system will be flat-picked up from sticking places, making it suitable for these cases.

Welding Clamping: Welding involves using magnetic chucks as efficient clamping devices when working on pipe sections and steel plates. Electromagnetic permanent magnets for clamp welding are superior to any other current form of clamping due to their powerful adhesive capabilities, dependability, and user-friendliness.

Factors To Consider When Using A Magnetic Chuck

For a magnetic chuck, several things should be taken into account to achieve the best possible performance and enhance safety:

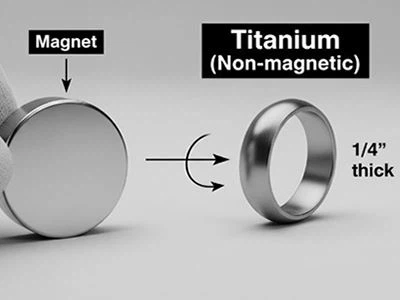

Workpiece Material

Concerning the employment of a magnetic chuck, the composition of the material in workpieces must be considered. Magnetic chucks are intended for holding on to ferrous materials tightly, and therefore, one must ensure that the workpiece is made of something that can be attracted by magnetic force. Non-ferrous materials may require other fixturing means, like mechanical clamps or vacuum chucks, to avoid movement during machining.

Chuck Size and Shape

The size and shape of the workpiece should match those of the magnetic chuck to obtain proper alignment and maximum holding force. If a small chuck is chosen instead, there might be an inadequate contact area, resulting in decreased holding forces, which would allow for some movement of the workpiece while machining. In addition, incorrectly shaped chucks will lead to irregular fixture pressure and reduced machining precision.

Magnetic Force

Deforming or destroying the workpiece should influence the adjusting magnetic force exerted by the chuck. Excessive magnetic force can lead to bending or distorting thin or delicate workpieces, while not having enough may result in slippage and insufficient holding of the workpiece during machining. The careful adjustment of the magnetic force will give you perfect clamping without affecting the quality of machining operations.

Surface Condition

The condition of a working surface on which a magnet chuck is placed is very important for maintaining maximum holding power and degree of accuracy for manufacturing purposes. Ensure that it is clean, flat, and free from debris or any other contaminations before putting your item on it. Any inconsistencies or defects on its surface contribute much towards failing to fix an item and achieving poor results after processing, thus ending up with some inaccuracies and faults in finished products.

Safety Precautions

Safety measures must be considered when using a magnet chuck to avoid accidents or injuries. Do not hold hands or fingers between the chuck and the machined object whenever it is on because severe injuries resulting from trapping may occur due to strong magnetic pull. Furthermore, follow all instructions the manufacturer gives regarding the safe use and maintenance of a magnet chuck to minimize such risks while using these machines safely and correctly.

Maintenance And Safety Considerations

Regular maintenance is vital to ensure magnetic chucks' best performance and longest life span. Some factors to consider during maintenance and safety include;

Cleaning: In some instances, clean the surface of a magnet chuck to remove substances that might tarnish it.

Inspection: Periodically check for any signs of wear or damage like cracks or an unevenly wearing surface.

Electrical Safety: Ensure proper electrical connections are maintained in electromagnetic chucks to prevent complications or hazards.

Proper Storage: Place magnetic chucks in a neat, dry place free from moisture and extreme temperatures, which may result in damage.

Conclusion

Magnetic chucks remain vital tools within machining and manufacturing industries, enabling secure holding of workpieces involved in various operations. Comprehension of how they operate, their types, advantages, applications, and what maintenance issues need to be considered is essential for optimal utilization to guarantee safe and effective machining activities.